Expect More

Matt Meyers

- Thinking

- March 12, 2024

It’s time we expect more of ourselves and our industry

The wholesale lumber market is in a cycle of self-perpetuating inefficiency. Incumbent inertia is a massive black hole where the young and optimistic are crushed by the epic gravitational pull of telephones, notepads, and “this is how we’ve always done it.”

A recent job posting for a commodity lumber purchasing director lists the following two key aspects of the job: 1) The ability to spend long periods of time on the phone, and 2) the ability to sit for long periods of time. Those aspects are sure to suck the bright, enthusiastic life out of the next generation of optimistic, efficiency seeking, business entrepreneurs. It probably wasn’t a strategic decision to create an unappealing job description, but the absence of a strategically curious question like “How do we attract the best and brightest talent to our company?” The black hole of “this is how we’ve always done it” wins again!

In my 28 lumber-industry years, the last 4 building a technology company fighting the black hole, I have heard all the reasons for the inertia. From “technology won’t work in this industry,” to “this industry is full of people who are slow to change.” I argue neither are true nor foregone conclusions that anchor us to sitting and talking on the phone until we are wheeled out on the chair we spent our career sitting on. Technology and behavior change are just excuses. The real barrier is the low expectations we set for ourselves and our industry.

The fragmented web of self-reinforcing inefficiency

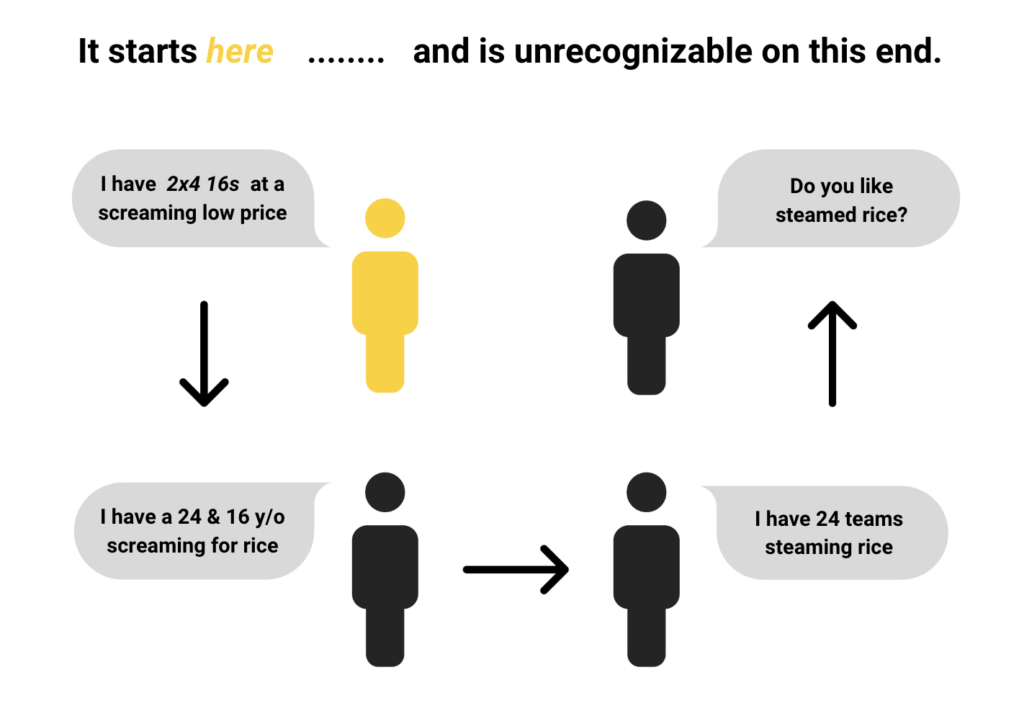

Did you ever play the telephone game as a kid? You sit in a circle and someone starts with a secret whispered in their neighbor’s ear. When the circle of whispers comes back to the originator, she bursts out laughing and exposes the initial secret and everyone joins the comedic chorus of laughter.

The telephone game in our industry is…the telephone. Data at the mill is structured, formatted and searchable in an ERP. The seller at the mill then converts data to a verbal or email offer in text, tables, or pdfs. The next trader does the same, in their own verbal or email shorthand. By the time the buyer sees it there is vague resemblance to the original source. It is unstructured, unformatted, unsearchable and scattered across buyer’s email, texts, and phone log (yellow pad).

The game converts clean data into unstructured information REQUIRING all the steps in the telephone transfer of information in both directions to translate backwards and forwards between each intermediary step! Thus, fragmented inefficiency begets fragmentation and inefficiency! And it comes at a high cost: errors, re-traded loads, and extra mark-ups left on the table by sellers at the mills and their preferred wholesale trading partners.

Technology and behavior change are not problems…low expectations are the problem.

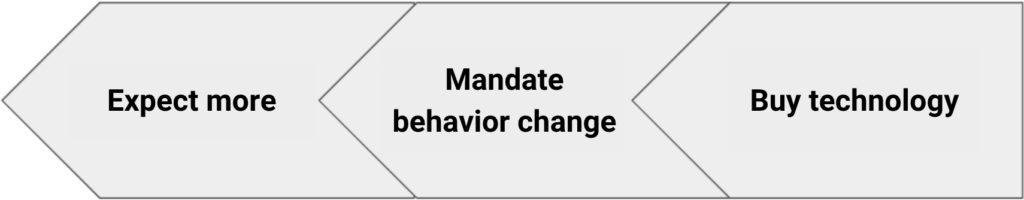

Why is the massive inertia resisting technology and behavior change? Because we focus on the wrong things – the tech and behaviors.

Most leaders who think about solving problems with technology start the wrong way – with technology:

This is wrong for two reasons:

- Innovation starts with a vision – a new expectation for what can be done.

- Behavior mandates inspire inertia, not innovation from internal entrepreneurs.

Instead, leaders should approach a technology opportunity with a high expectation, reinforce the behaviors that meet the expectation, then get out of the way!

In a similar sequence, spending should follow adoption, not lead or mandate it.

The lumber industry is full of past, painful technology deployments led in reverse.

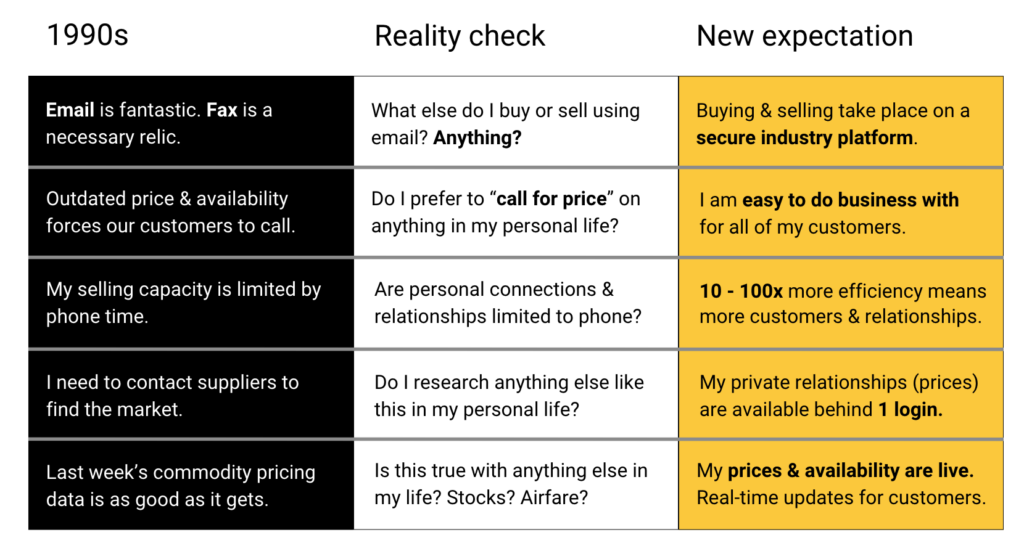

Raise your expectations, because the technology is here today!

Technology is not holding this industry back. Instead, it’s the expectation we have of ourselves and our industry. The black hole of “this is how we do it” inertia is perpetuating inefficiency.

But there is light starting to escape the black hole as a new expectation starts to take hold. The reality check will point out the absurdity of our ways and the 1990s will snap back to where they belong, along in their reverse-pleat Dockers with pagers affixed to braided leather belts.

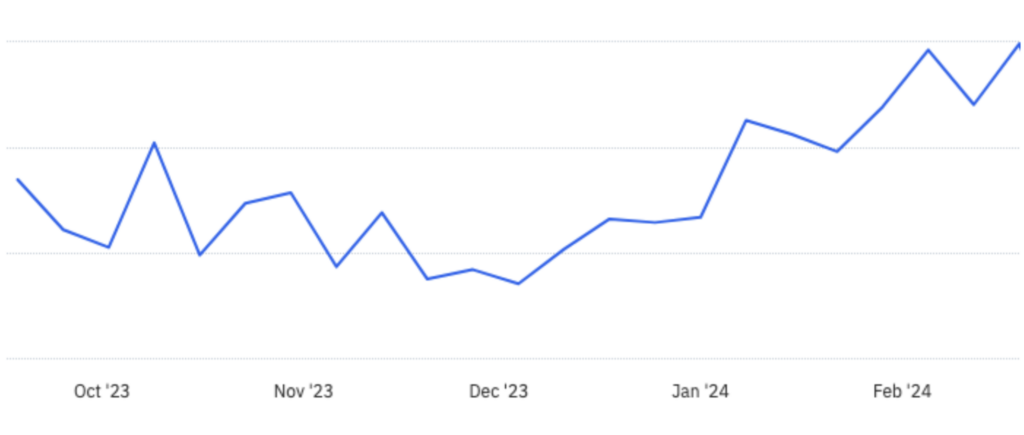

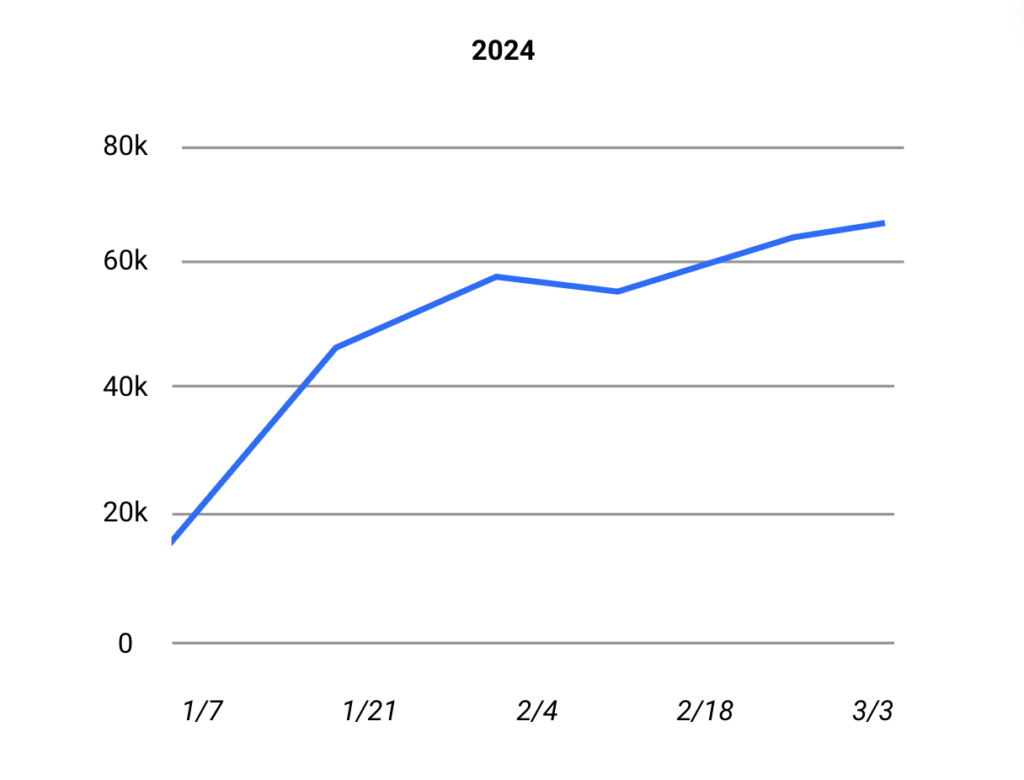

Using platform data, the communication traffic on the Yesler platform nearly doubled since Fall:

The number of loads shared weekly by Yesler users with their private trading partners continues to grow after the initial spike from the January release. Some sellers share thousands of loads per week. Some buyers already have hundreds of loads per day on their digital desktops from their trusted suppliers.

Will the story told in today’s telephone game have anyone’s ear on the receiver tomorrow? Or will it be lost in someone’s inbox? The answer lies in what you expect of yourself and your industry.